Summary

Video:

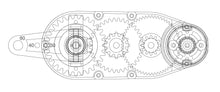

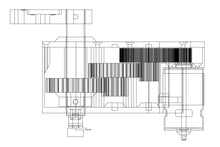

This servo/gear reduction uses mostly 3D-printed parts. The servo uses a 775 36V 9000rpm brushed DC-motor which is driven by a BTS7960B motor driver which is controlled by an Arduino mega 2560. The stall torque of the servo is about 55kg/cm which is about 5.39 Nm. the peak current is about 18 amps when using a 6s LIPO battery (about 22-24V). the reduction ratio is 1:30.

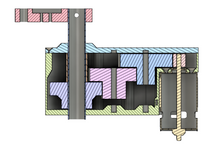

For the intend of filming the internals of the servo for possible failures, the gears were printed in different colors and a 5mm acrylic lid was laser cut. Unfortunately I didn't get to film any awesome footage of gears exploding because they were far to strong. Even at a peak torque of 54kg/cm they didn't show the slightest form of flexing or cracks.

The two middle gears (blue and red one) use a stainless steel shaft of 6mm diameter. The holes of the gears are designed at 6.2mm diameter so they would fit nicely around the 6mm shaft but some additional filing/sanding might be required. The same might has to be done for the 20mm shaft holes.

A DXF file of the lid has been uploaded so people with a laser cutter can cut the lid out of transparent acrylic.

The STL-files option includes these files:

-Individual STL-files

The Fusion 360 source files option includes these formats:

-.f3d

-.obj

-.stp/.step

-.3mf

-.fbx

-.skp

-.smt

-.ipt files

Part list, schematics, code and more info about this project can be found here

Printer used:

Flsun Q5

Supports:

Yes

Resolution:

0.2

Infill:

25-30%

3-5 outer perimeters

The 3D-printers, tools and materials I'm using for these projects can be found here: Tools and materials – bbprojects

Note: This is not a physical product. When you're purchasing the STL or Fusion 360 source files you will be able to download these files. A physical product will not be send to your address.

All my designs are licensed according to the CC BY-NC-ND, unless specified differently. license: https://creativecommons.org/licenses/by-nc-nd/4.0/