Summary

Video:

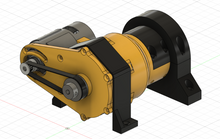

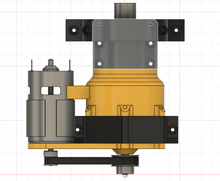

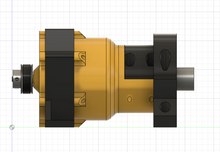

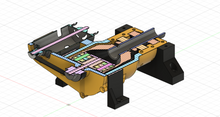

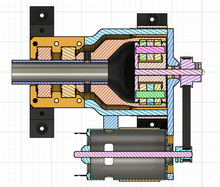

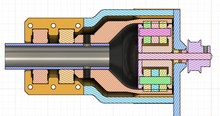

I was fascinated by this type of gearbox and always wanted to make one. This type of gearbox is one of the most used in industrial robots. This type of gearbox only has a single reduction (in this case 2 because of the belt reduction) with a very high reduction ratio. Because of the single stage reduction there's almost no tolerance/play between input and output shaft. Conventional gearboxes use more gears to achieve the same reduction ratio, the tolerances between the gears add up resulting in greater tolerances/play between the input and output shaft.

Here are some specifications of the gearbox:

Max tested torque at 12V: 41.3kg*cm or 4N*m

Circular spline teeth amount: 50 teeth

Flex spline teeth amount: 48 teeth

Small GT2 pulley: 16 teeth

Big GT2 pulley: 36 teeth

reduction ratio strain wave gear: (48 - 50)/48 = -0.0416

1/0.0416 = 24.038

Reduction ratio = 24.038:1

Reduction ratio belt drive: 36/16= 2.25

Reduction ratio = 2.25:1

Total reduction ratio = 54.0855:1

The STL-files option includes these files:

-Individual STL-files

The Fusion 360 source files option includes these formats:

-.f3d

-.obj

-.stp/.step

-.3mf

-.fbx

-.skp

-.smt

-.ipt files

Part list, schematics, code and more info about this project can be found here

Printer used:

Flsun Super Racer

Supports:

Yes

Resolution:

0.2

Infill:

25-30%

The 3D-printers, tools and materials I'm using for these projects can be found here: Tools and materials – bbprojects

Note: This is not a physical product. When you're purchasing the STL or Fusion 360 source files you will be able to download these files. A physical product will not be send to your address.

All my designs are licensed according to the CC BY-NC-ND, unless specified differently. license: https://creativecommons.org/licenses/by-nc-nd/4.0/