Summary

Video:

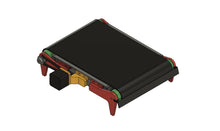

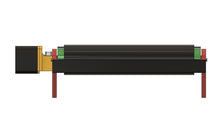

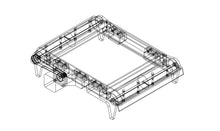

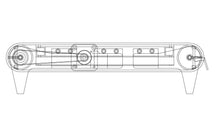

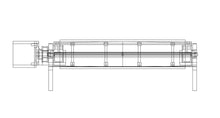

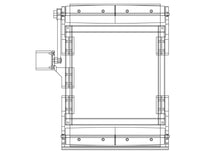

I needed a way to print a lot small parts (cable chain pieces) fast and preferably in an automated way, so I build this modular delta belt 3D-printer for (small) automated series productions. It combines the best of both worlds, the speed of the delta printer and the automation of the conveyor belt.

This design is mainly focused on series production (print a lot of parts in an automated way) and not so much on continuous printing (print very long pieces). The main reason for this is that for continuous printing the head needs to be tilted 45 degrees, which requires a lot of hardware changes to be made to the printer itself. With this design you need to make exactly 0 changes to the hardware and even the firmware of the printer (FLsun Q5 in my case). The belt is designed to be completely modular.

The belt is triggered by a limit switch which in turn is triggered by the homing sequence of the printer itself. The amount of parts you want to print can be chosen by copying and pasting the G-code the amount of times you want the part to print. I tried using some for loops in the G-code but the firmware of the FLsun Q5 doesn't seem to except these codes.

The STL-files option includes these files:

-Individual STL-files

The Fusion 360 source files option includes these formats:

-.f3d

-.obj

-.stp/.step

-.3mf

-.fbx

-.skp

-.smt

-.ipt files

Part list, schematics, code and more info about this project can be found here: Delta belt 3D-printer for automated series production – bbprojects

Printer used:

Flsun Super Racer

Supports:

Yes

Resolution:

0.2

Infill:

25-30%

The 3D-printers, tools and materials I'm using for these projects can be found here: Tools and materials – bbprojects

Note: This is not a physical product. When you're purchasing the STL or Fusion 360 source files you will be able to download these files. A physical product will not be send to your address.

All my designs are licensed according to the CC BY-NC-ND, unless specified differently. license: https://creativecommons.org/licenses/by-nc-nd/4.0/